News Report: The Made-in-Singapore Edge: Part 2 (ST 20060305)

The following is Part 2 of the report in Singapore's Sunday Times about Singapore's defence technnology making an impact locally and abroad.

*********

KEEPING UP WITH THE BIG BOYS

In Part 1 of our two-part series on the Singapore defence industry, we focused on ground-breaking, locally developed weapons and systems for the third-generation Singapore Armed Forces (3G SAF). In Part 2 today, we take a look at how Singaporedevelops a competitive advantage in the fiercely contested worlds arms market.

by Felix Soh

In the nasty and brutish global defence business, one cannot expect life to be fair and square.

The industry's big boys - the Americans, Eurpoeans and the Russians - have no qualms about going for the jugular when chasing markets for their products, leaving smaller upstarts like Singapore by the wayside.

"Defence companies are fighting tooth and nail to win contracts," said Mr Steve Meighan, regional managing director (Asia-Pacific), BAE Sstems, the fourth largest defence company in the world in terms of revenue.

If competition is already intense for the big companies, it is much, much tougher for the smaller players.

They have to make up for their lack of size by doing some strategic jiu jitsu - for instance, producing unique and better weapons and systems, focusing on niche products such as equipment for homeland security, targeting non-traditional markets and entering into partnerships with the big boys.

They must also be nimble and deft in customising and adapting their products to the needs of potential customers.

It is through the interplay of these initiatives that the smaller players can stay afloat - and even thrive.

Siad Mr Patrick Choy, chief marketing officer of Singapoer Technologies Kinetics:"We make an impact on the market by creating better products with differentiating features."

ST Kinetics is the land systems arm of Singapore Technologies Engineering, which is ranked 53rd in the Defense News Top 100 list of the world's top 100 leading defence companies.

In Asia, only two Japanese companies (Kawasaki Heavy Industries and Mitsubishi Electric) and an Indian one (Hindustan Aeronautics) - much bigger and more mature organisations - surpass ST Engineering in the authoritative listing.

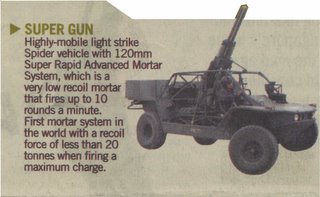

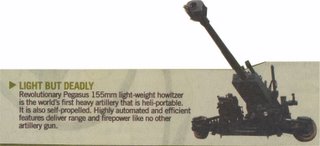

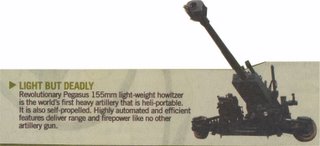

Over the years, the company has made a strong imprint on the global defence market with a number of ground-breaking home-grown products, such as its revolutionary Pegasus 155mm light-weight howitzer, the world's first heavy artillery that is heli-portable.

But, often, having a superior product is not enough. Other more powerful forces collude against the outsider and smaller player.

A classic case in point is Singapore's Ultimax 100 Squad Automatic Weapon (SAW), which was in contention for the US Army's choice of SAW in 1980s.

In the ocntest, the Ultimax - developed by Singapore and in service with the SAF and in some other countries - was clearly the better weapon.

Its recoil is so light that it could be held up against the chin and fired at full auto without hurting the firer.

But it eventually lost to the Belgian-made FN M249 Minimi, a weapon now derided as being "too heavy and not sufficiently reliable or accurate".

DefenseReview.com, the online tactical technology magazine, is blunt in its assessment of the Minimi. It said: "(It) should have been replaced a long time ago."

In contrast, it noted that "the Ultimax is lighter, more controllable, more reliable in adverse conditions and faster to reload than the M249".

Well-known arms expert Charles Cutshaw rated the Ultimax as the best light machine gun and SAW in the world today.

Industry sources noted that the fact that the Minimi's manufacturer, Belgium, is a partner of the US in the North Atlantic Treaty Organisation (NATO) was a major influence over the selection of the European weapon.

Despite the difficult marketing environment, ST Engineering has scored some notable successes:

* CIS 40mm Automatic Granade Launcher (CIS 40 AGL): Singapore is No. 2 in the world in terms of the number of AGLs sold to more more than 20 countries. The versatile CIS 40 AGL is modular in construction and needs little maintenance.

* SAR 21: ST Engineering has broken into the export market for the rifle, now the standard weapon of the SAF infantry men, by selling an undisclosed nummber to an African country. The low-recoil SAR 21's optical scope and laser-aiming device enhance its accuracy, making it the ideal weapon for quick target engagement.

* Bronco All Terrain Tracked Carrier: It can carry an unprecedented payload of up to five tonnes. A European country is looking for a Bronco-type requiremetn. ST Engineering is now awaiting the revised RFP (Request for proposal) and quotation of the final price.

* Fast missile craft: ST Engineering's shipyard in the US, VT Halter Marine, won a US$28.8 million (S$46.7 million) contract to develop a functional design of fast missile craft for the Eygptian Navy.

* 40mm self-destruct round: ST Engineering broke into the market in the Nordic countries by selling them its unique 40ABMS round which self-destructs. This reduces the occurrence of blinds that are potentially hazardous.

* Simulators: ST Electronics, a recognised leader in the field of simulation and training in both the military and commercial sectors, has been successful in selling simulators overseas.

* F-5 fighter aircraft upgrades: Singapore Technologies Aerospace, Aircraft Maintenance & Modification (AMM) holds the record for delivering hte most number of F-5 upgrade programmes in the world

ST Engineering started as an organisation to support the SAF, then grew in tandem with it to become a company with comepetency to design and develop its own weapons and systems.

The SAF it its main customer but it does not generate enough volume. So, the company has to pursue an aggressive export programme. If it can sell more of a product, the cost per unit will be lower.

However, the going is not easy as the defence procurement process in any country has a very long gestation period.

To succeed, the Singapore defence industry has to stay ahead of the curve. Commented Mr Choy: "The trend now is the modernisation of armed forces which invovles harnessing the potential of technolgoy. We, as a company, have also to transform to keep pace and to be ahead."

This means being a centre of excellence and pumping money into research and development.

Other than being sharp enough to spot trends, it must be able to identify the right technolgies to develop, especially those with dual use - that is, for civilian and military use.

ST Engineering used to build armoured vehicles exclusively to meet military requirements. This was an expensive exercise.

Today, the company is taking a different look at compoenents available in the market. Increasingly, the tendency is to use off-the-shelf material.

It used a vehicle built for civilian use, a twin-cabin pick-up, to build its Light Armoured Multi-Role Vehicle. In essence, it combined commercially proven automotive components with modified, off-the-shelf chassis to produce a cheaper fully-armoured 4x4 vehicle ideal for the urban battlefield.

In some ways, being small can be an asset rather than an advantage.

Small equals agility and flexibility. For example, the US defence development and procurement system is too huge and cumbersome for the Americans to develop weapons quickly. Bureaucratic red tape also slows the process. Singapore, being smaller, can move faster.

Looking into the immediate future, influencing customers and winning contracts will be an even more daunting challenge.

The answer lies in partnerships and acquisitions.

For difficult markets, like the plum US market, the most effective way to make inroads is to acquire an American company.

Sad Mr Coy: "To penetrate the US market, you have to be a US company. That's why we are making a number of acquisitions in the US. For example, we acquired an American copany that sells ruggedised computers to the US Army."

Ultimately, the Singaporebrand name and having the SAF as its prime customer are the biggest plus points. THat's because Singapore and SAF are viewed as benchmarks of quality.

Said Mr Choy: "The SAF has a reputation that makes it an important reference customer.

"As a user and key customer, it is very demanding and this drives ST Engineering."

*********

KEEPING UP WITH THE BIG BOYS

In Part 1 of our two-part series on the Singapore defence industry, we focused on ground-breaking, locally developed weapons and systems for the third-generation Singapore Armed Forces (3G SAF). In Part 2 today, we take a look at how Singaporedevelops a competitive advantage in the fiercely contested worlds arms market.

by Felix Soh

In the nasty and brutish global defence business, one cannot expect life to be fair and square.

The industry's big boys - the Americans, Eurpoeans and the Russians - have no qualms about going for the jugular when chasing markets for their products, leaving smaller upstarts like Singapore by the wayside.

"Defence companies are fighting tooth and nail to win contracts," said Mr Steve Meighan, regional managing director (Asia-Pacific), BAE Sstems, the fourth largest defence company in the world in terms of revenue.

If competition is already intense for the big companies, it is much, much tougher for the smaller players.

They have to make up for their lack of size by doing some strategic jiu jitsu - for instance, producing unique and better weapons and systems, focusing on niche products such as equipment for homeland security, targeting non-traditional markets and entering into partnerships with the big boys.

They must also be nimble and deft in customising and adapting their products to the needs of potential customers.

It is through the interplay of these initiatives that the smaller players can stay afloat - and even thrive.

Siad Mr Patrick Choy, chief marketing officer of Singapoer Technologies Kinetics:"We make an impact on the market by creating better products with differentiating features."

ST Kinetics is the land systems arm of Singapore Technologies Engineering, which is ranked 53rd in the Defense News Top 100 list of the world's top 100 leading defence companies.

In Asia, only two Japanese companies (Kawasaki Heavy Industries and Mitsubishi Electric) and an Indian one (Hindustan Aeronautics) - much bigger and more mature organisations - surpass ST Engineering in the authoritative listing.

Over the years, the company has made a strong imprint on the global defence market with a number of ground-breaking home-grown products, such as its revolutionary Pegasus 155mm light-weight howitzer, the world's first heavy artillery that is heli-portable.

But, often, having a superior product is not enough. Other more powerful forces collude against the outsider and smaller player.

A classic case in point is Singapore's Ultimax 100 Squad Automatic Weapon (SAW), which was in contention for the US Army's choice of SAW in 1980s.

In the ocntest, the Ultimax - developed by Singapore and in service with the SAF and in some other countries - was clearly the better weapon.

Its recoil is so light that it could be held up against the chin and fired at full auto without hurting the firer.

But it eventually lost to the Belgian-made FN M249 Minimi, a weapon now derided as being "too heavy and not sufficiently reliable or accurate".

DefenseReview.com, the online tactical technology magazine, is blunt in its assessment of the Minimi. It said: "(It) should have been replaced a long time ago."

In contrast, it noted that "the Ultimax is lighter, more controllable, more reliable in adverse conditions and faster to reload than the M249".

Well-known arms expert Charles Cutshaw rated the Ultimax as the best light machine gun and SAW in the world today.

Industry sources noted that the fact that the Minimi's manufacturer, Belgium, is a partner of the US in the North Atlantic Treaty Organisation (NATO) was a major influence over the selection of the European weapon.

Despite the difficult marketing environment, ST Engineering has scored some notable successes:

* CIS 40mm Automatic Granade Launcher (CIS 40 AGL): Singapore is No. 2 in the world in terms of the number of AGLs sold to more more than 20 countries. The versatile CIS 40 AGL is modular in construction and needs little maintenance.

* SAR 21: ST Engineering has broken into the export market for the rifle, now the standard weapon of the SAF infantry men, by selling an undisclosed nummber to an African country. The low-recoil SAR 21's optical scope and laser-aiming device enhance its accuracy, making it the ideal weapon for quick target engagement.

* Bronco All Terrain Tracked Carrier: It can carry an unprecedented payload of up to five tonnes. A European country is looking for a Bronco-type requiremetn. ST Engineering is now awaiting the revised RFP (Request for proposal) and quotation of the final price.

* Fast missile craft: ST Engineering's shipyard in the US, VT Halter Marine, won a US$28.8 million (S$46.7 million) contract to develop a functional design of fast missile craft for the Eygptian Navy.

* 40mm self-destruct round: ST Engineering broke into the market in the Nordic countries by selling them its unique 40ABMS round which self-destructs. This reduces the occurrence of blinds that are potentially hazardous.

* Simulators: ST Electronics, a recognised leader in the field of simulation and training in both the military and commercial sectors, has been successful in selling simulators overseas.

* F-5 fighter aircraft upgrades: Singapore Technologies Aerospace, Aircraft Maintenance & Modification (AMM) holds the record for delivering hte most number of F-5 upgrade programmes in the world

ST Engineering started as an organisation to support the SAF, then grew in tandem with it to become a company with comepetency to design and develop its own weapons and systems.

The SAF it its main customer but it does not generate enough volume. So, the company has to pursue an aggressive export programme. If it can sell more of a product, the cost per unit will be lower.

However, the going is not easy as the defence procurement process in any country has a very long gestation period.

To succeed, the Singapore defence industry has to stay ahead of the curve. Commented Mr Choy: "The trend now is the modernisation of armed forces which invovles harnessing the potential of technolgoy. We, as a company, have also to transform to keep pace and to be ahead."

This means being a centre of excellence and pumping money into research and development.

Other than being sharp enough to spot trends, it must be able to identify the right technolgies to develop, especially those with dual use - that is, for civilian and military use.

ST Engineering used to build armoured vehicles exclusively to meet military requirements. This was an expensive exercise.

Today, the company is taking a different look at compoenents available in the market. Increasingly, the tendency is to use off-the-shelf material.

It used a vehicle built for civilian use, a twin-cabin pick-up, to build its Light Armoured Multi-Role Vehicle. In essence, it combined commercially proven automotive components with modified, off-the-shelf chassis to produce a cheaper fully-armoured 4x4 vehicle ideal for the urban battlefield.

In some ways, being small can be an asset rather than an advantage.

Small equals agility and flexibility. For example, the US defence development and procurement system is too huge and cumbersome for the Americans to develop weapons quickly. Bureaucratic red tape also slows the process. Singapore, being smaller, can move faster.

Looking into the immediate future, influencing customers and winning contracts will be an even more daunting challenge.

The answer lies in partnerships and acquisitions.

For difficult markets, like the plum US market, the most effective way to make inroads is to acquire an American company.

Sad Mr Coy: "To penetrate the US market, you have to be a US company. That's why we are making a number of acquisitions in the US. For example, we acquired an American copany that sells ruggedised computers to the US Army."

Ultimately, the Singaporebrand name and having the SAF as its prime customer are the biggest plus points. THat's because Singapore and SAF are viewed as benchmarks of quality.

Said Mr Choy: "The SAF has a reputation that makes it an important reference customer.

"As a user and key customer, it is very demanding and this drives ST Engineering."